Restoration of the Barvue mine

Our eco-engineering team was mandated to undertake a series of essential actions to re-establish the ecological balance.

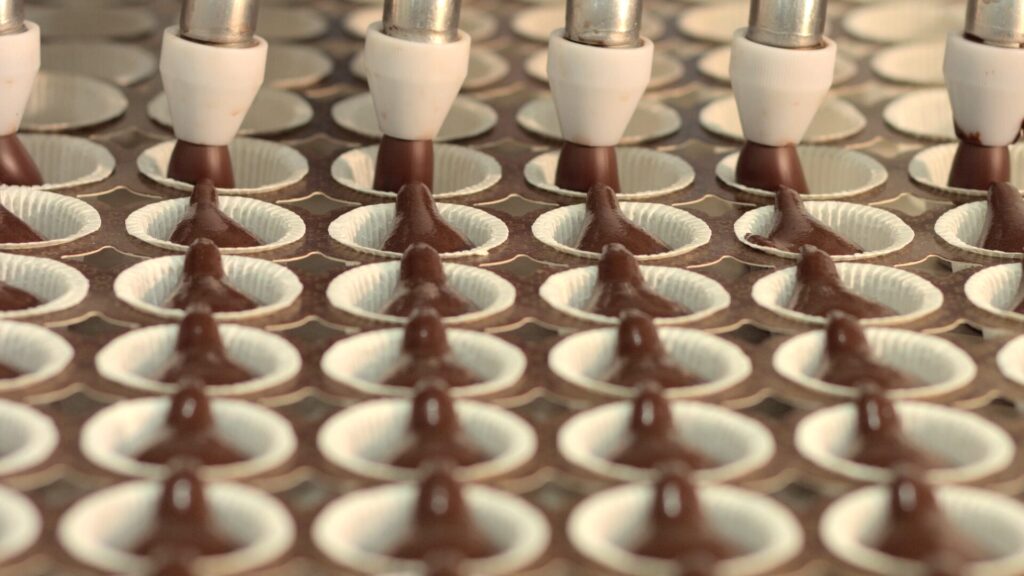

The agri-food: a sector where quality is at the heart of every stage in the production and distribution chain

Complete solutions including design studies, purchasing, equipment acceptance, installation follow-up and project commissioning.

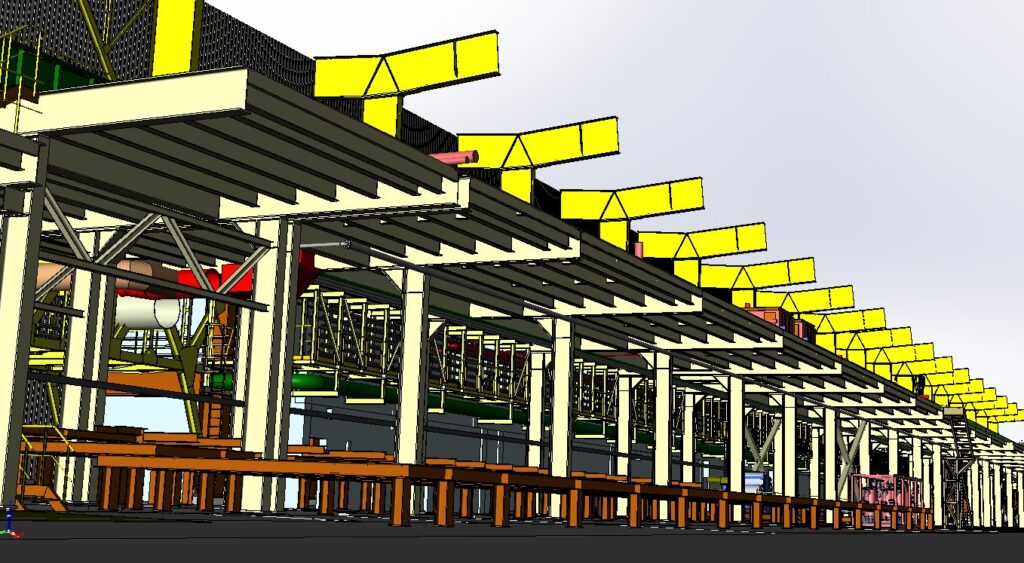

The mechanical engineering : the field where design meets innovation

For over twenty-five years, Artelia has been designing and implementing optimized solutions tailored to the specific requirements of its customers’ industrial projects. The Group operates in a wide range of sectors, including aeronautics, space, automotive, rail, naval, defense, renewable energies, nuclear, steel, petrochemicals and agrifood.

Decarbonizing the industry

The demand for goods, equipment, and energy has increased in line with the growth of the global population and the aspiration of most populations to have a high level of comfort and service. This demand is met by an industrialized and globalized production system that heavily relies on hydrocarbons and coal. As a major contributor to greenhouse gas (GHG) emissions, the industry is targeted by policies aimed at reducing carbon footprint caused by human activities. The industry faces a dual challenge: decarbonizing its production processes and transitioning manufacturing towards low-carbon products capable of contributing to the overall GHG emissions reduction.

Romain Allais, one of Artelia’s specialists in industrial decarbonization, presents the several levers currently being activated or considered to drive this change.

ArcelorMittal Mardyck

Creation of an electrical steel production unit

Healthcare sovereignty and pharmaceutical manufacturing

The Covid-19 pandemic of 2020 revealed the extent to which European nations depend on imports of medicines and the active pharmaceutical ingredients essential to their manufacture. The issue of healthcare sovereignty was thus raised once again at an EU level and a number of member states declared their desire to secure their supplies of medicines, in particular by relocating industrial production and boosting their domestic capabilities. David Papillon, who is overseeing for Artelia the design of the Seqens paracetamol plant in Roussillon (SE France), tells us what he has learned about this new movement taking shape in France.

Aalborg University Hospital’s thalassothermal system

Aalborg University Hospital’s thalassothermal system Using lake water to heat and cool a new hospital The cement manufacturer Aalborg Portland uses massive quantities of chalk in its production process. Many excavations have over time formed a chalk lake at the company’s facilities, and this now provides district cooling for the new Aalborg University Hospital. The […]

STMicroelectronics Crolles

Expansion of electronic chip manufacturing capacity

Soitec Bernin

Extension d’une usine de fabrication de matériaux semi-conducteurs

STMicroelectronics Bouskoura

Expansion of chip manufacturing and test capabilities